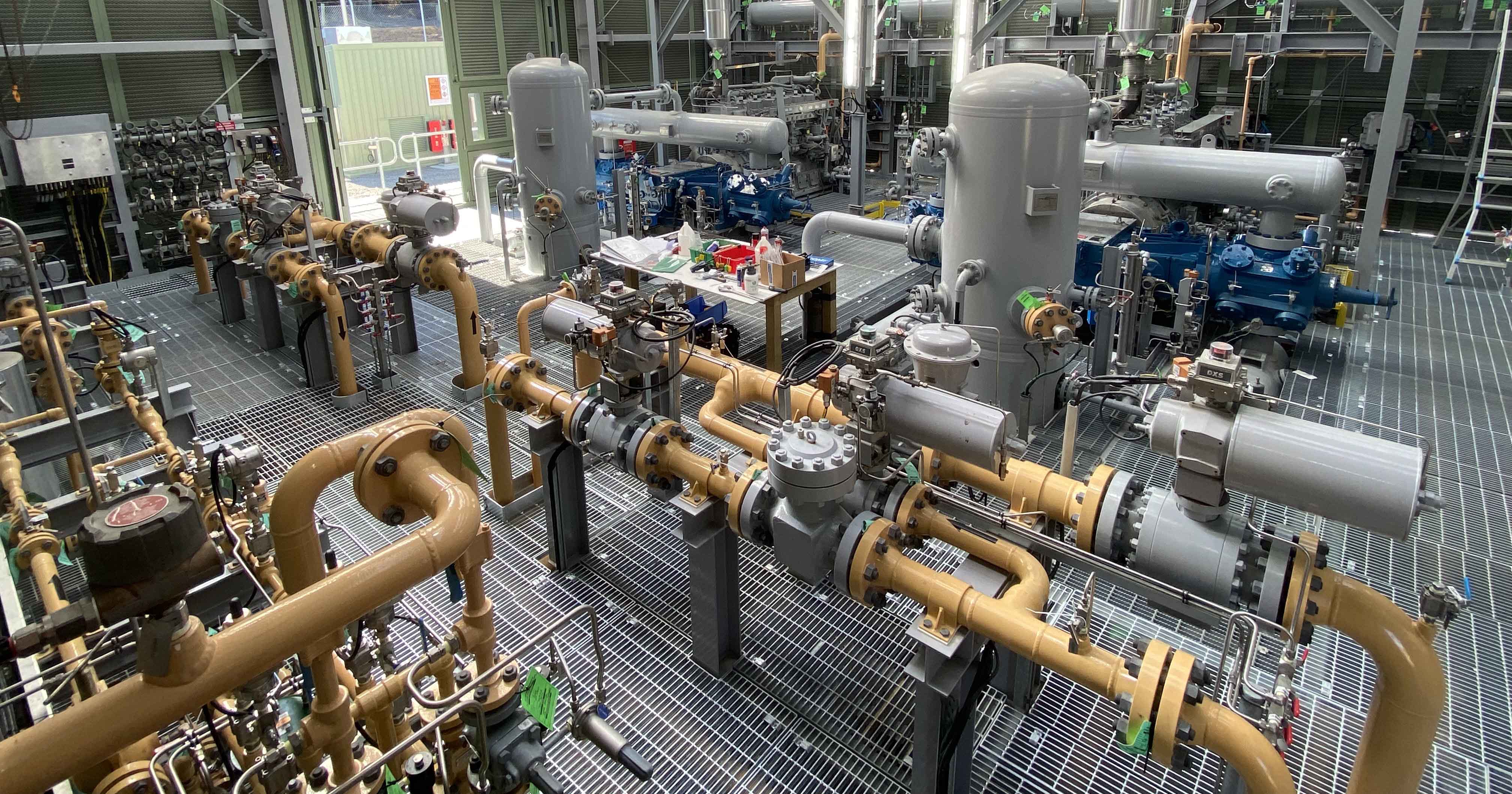

A multi million upgrade to the Firstgas compressor station at Kaitoke is now substantially complete, on schedule and within budget. Two state-of-the-art compressors from the USA have been installed, commissioned, and are ready to be brought online in early 2026.

Simon Pease, Firstgas

The four-year project has been a major success, said Simon Pease, Manager of Project Delivery and Asset Management for Firstgas.

“Not only was the upgrade on time and under budget, but the quality of the finished site is really good. I think it’s likely been the best major project we’ve ever run, and there’s a lot we’ll take from it and apply to our smaller, more frequent projects.”

Kaitoke compressor Station

Improvements in efficiency, consistency and risk reduction

The compressor upgrade at Kaitoke, south of Whanganui, delivers several important benefits. The new compressors are appropriately sized for current and future demand, significantly more efficient and improve Firstgas’s ability to respond during peak periods or when gas is needed to support the electricity system. The upgrade also enhances the reliability of supply to the Southern System, which services Wellington and Hawke’s Bay, and makes system management easier.

In addition, it reduces reliance on the ageing Kapuni compressors from the 1970s, lowering overall network costs.

“Kaitoke will be significantly more efficient, and the supply to the Southern System will be more consistent,” says Pease. “While customers won’t notice any difference, the upgrade helps us manage gas during busy periods, ensuring we maintain the reliable pressure standard we aim for. This matters because homes, businesses and industry all depend on a consistent gas supply.”

Kaitoke compressor Station

New compressors expected to last for decades

The old compressors at Kaitoke date back to the early 1980s, and some of the compressors in New Zealand date back to the 1970s. The science of compression remains generally unchanged, says Pease, so compressors can last for many decades. However, the efficiency has improved significantly.

“Compression itself doesn’t change, it’s the same principle now as it has been since it was invented,” he explains. “That means that as long as you maintain your compressors, and we do, they’ll continue to run reliably. What has changed is that the modern compressors give us much more control, and they operate much more efficiently.”

Compressor upgrades are also on the cards at Firstgas’ Rotowaro Compressor Station, north of Hamilton. Similar to the units at Kaitoke, the Rotowaro compressors are from the 1980s and are due to be replaced.

“The current Rotowaro compressor mix isn’t quite right for future needs,” says Pease. "Given their age we will retire some and replace some. The gas volumes have changed; these machines were designed to push higher loads of gas through the pipeline. But we don’t need as much pressure in the network as we used to and by operating at lower pressure, it places less demand on the network and lowers the integrity risk.”

Emissions reduction expected

Another satisfying aspect of the Kaitoke project is the emissions reduction that is expected once the new compressors are running in 2026.

“We have genuinely tried to do everything practicable to reduce emissions. We examined a number of options and new technology to find the best solution.”

Already commissioned and proven on site, the new compressors are due to be fully operational in the first quarter of 2026, when they will be connected to the new DCS system that provides remote operation for all the Clarus sites.

See more about what Firstgas is up to here.