The Firstgas Kaitoke Compressor site is being prepared for the arrival of two new state-of-the-art compressors in early 2025.

Kaitoke is a key site for the supply of natural gas throughout the lower North Island. Its existing 40-year-old compressor set-up isn’t enough to meet ongoing demand – especially on cold winter nights when gas usage peaks.

To solve that problem, Firstgas is installing a pair of new compressors that will keep up with the demand for gas and improve the network’s reliability and flexibility. More than 150 people are involved in this major project, with the compressors due to be switched on in April 2025.

New compressors are a step up in technology

The new compressors will be the right size to meet demand, they’ll be more efficient, and they’ll allow Firstgas to better respond to gas demand at peak times and when gas is needed to support our electricity system. They also include new technology that is a huge step up on the existing equipment, according to Ian Bayliss, Project Manager.

“There’s new engine management technology, catalytic converters on the exhausts that will enable the compressors to perform more efficiently, and reduce carbon emissions,” Bayliss explains.

The compressors are coming from Enerflex, Houston, which specialises in sustainable energy solutions and sells more than US$2 billion in compressors annually. Settling on the Enerflex compressor as the right choice for Kaitoke took a considerable amount of research. Bayliss and the team started thinking about how best to upgrade the facility in 2019 and undertook comprehensive studies through to 2023 before finally reaching a decision.

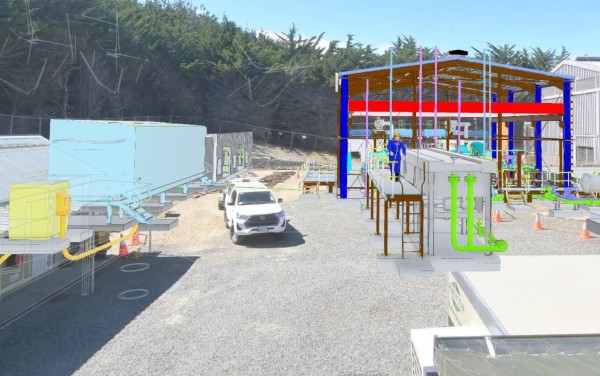

"A lot of the challenges came early on in this project, because the more layers we peeled off, the more questions we raised,” says Bayliss. “But we’re now in the detailed design phase and doing the preparatory site work. We’re currently constructing the buildings the compressors will go in when they arrive.”

Kaitoke compressor upgrade design

“It’s good to know you’re having a positive impact”

Watching years of planning beginning to come to fruition is one of the most enjoyable parts of the job for Bayliss. He has worked for Firstgas since 2017 and participated in some massive and vital infrastructure projects. In 2022, he managed the team that completed the Gilbert Stream Pipeline realignment, successfully replacing 400 metres of the critical Maui pipeline without any disruption to the gas supply to Auckland and Northland.

“Fundamentally I like building stuff – it gets me out of bed,” he says. “On these big projects it can feel like you’re doing endless design cycles, so to see things starting to be built at the Kaitoke site and seeing it come to life is quite satisfying.”

Another satisfying aspect of the Kaitoke project is the emissions reduction that is expected once the new compressors are running.

“We have genuinely tried to do everything practicable to reduce emissions. We examined a bunch of options and new technology to find the best solution.”

With a strong commitment to helping New Zealand meet its goal of net zero carbon by 2050, Clarus is actively researching, innovating and investing in renewable gas technologies, not only for the good of the country, but for the good our business, customers and employees too. See more about what Clarus is up to here.