Every day, natural gas travels quietly beneath our feet, powering homes, businesses, and industries across the North Island. Most of us never see the pipelines that make this possible, but ensuring their safety is a constant challenge.

At Firstgas, our job is to transport this energy safely and reliably through a vast underground network. And now, we’ve taken a major step forward with new world-leading inspection technology, used for the very first time in New Zealand.

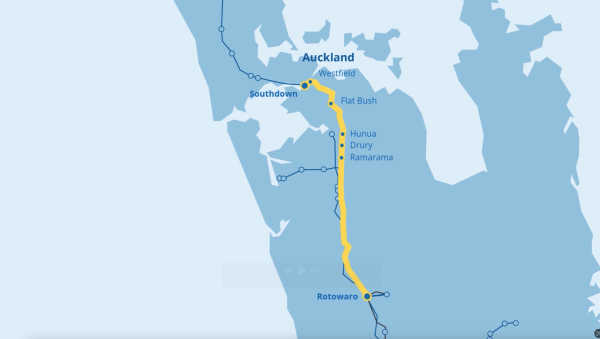

Earlier this year, our team trialled the Electromagnetic Acoustic Transducer (EMAT) tool, a highly specialised device designed to detect even the smallest cracks in pipelines. Launched into a 90-kilometre stretch of the Maui pipeline feeding Auckland, it represents a milestone for both our company and the country’s energy security.

Watch the video:

Bringing global expertise together

“The hours, dedication, and sacrifices they put in to get this off the ground really speak to their hard work and commitment,” said Bollman.

The project was led by Nicola Loft, Project Manager at Firstgas, who coordinated engineers, contractors, and international experts to make it possible. Supporting in the field was Senior Pipeline Engineer, Thomas Bollman, who oversaw the launch and retrieval of the tool on the day.

Thomas Bollman, Senior Pipeline Engineer

Bollman explained the importance of the project. “This is the first time we’ve run an EMAT tool in New Zealand, which is a big milestone. It’s a highly specialised piece of equipment. The primary purpose is to identify any linear crack-like indications in the pipeline. If we find them, we can remediate the line and ensure it continues to operate safely into the future.”

While the technology was critical, Bollman was quick to highlight the real success factor - the engineers and project team who know this system intimately.

“The hours, dedication, and sacrifices they put in to get this off the ground really speak to their hard work and commitment,” said Bollman.

The pipeline journey

The tool was launched from Rotowaro in the Waikato in the early evening and travelled through the pipeline overnight at the pace of a steady walk. By 11am the next morning, it had arrived at the South Down delivery point, completing a smooth 19-hour journey underground.

Seeing the tool safely retrieved was a proud moment for the team and a clear sign that the operation had gone to plan.

The data collected during the run is now being analysed at the Rosen Data Centre, where specialist engineers will interpret the results. Their analysis will confirm whether there are any hidden flaws or weaknesses in the pipeline and guide any remediation if required.

A milestone for New Zealand

The project is already being hailed as a success, not only for the safe and efficient run of the tool, but also for proving that New Zealand can deploy world-leading inspection technology to protect its critical energy infrastructure.

By detecting the invisible, Firstgas continues to keep its pipelines safe, reliable, and ready to deliver energy where it’s needed most.